Welcome to Hydro-Lazer Waterjet Cutting Services

Hydro-Lazer has been providing the very best in waterjet cutting and precision flooring inlays for over 30 years. With a wide range of services covering any type of project, we stand ready to help you bring your design plans to life.

Hydro-Lazer, Inc. has been a specialist in this cutting technique for nearly three decades and we continue to build on our legacy.

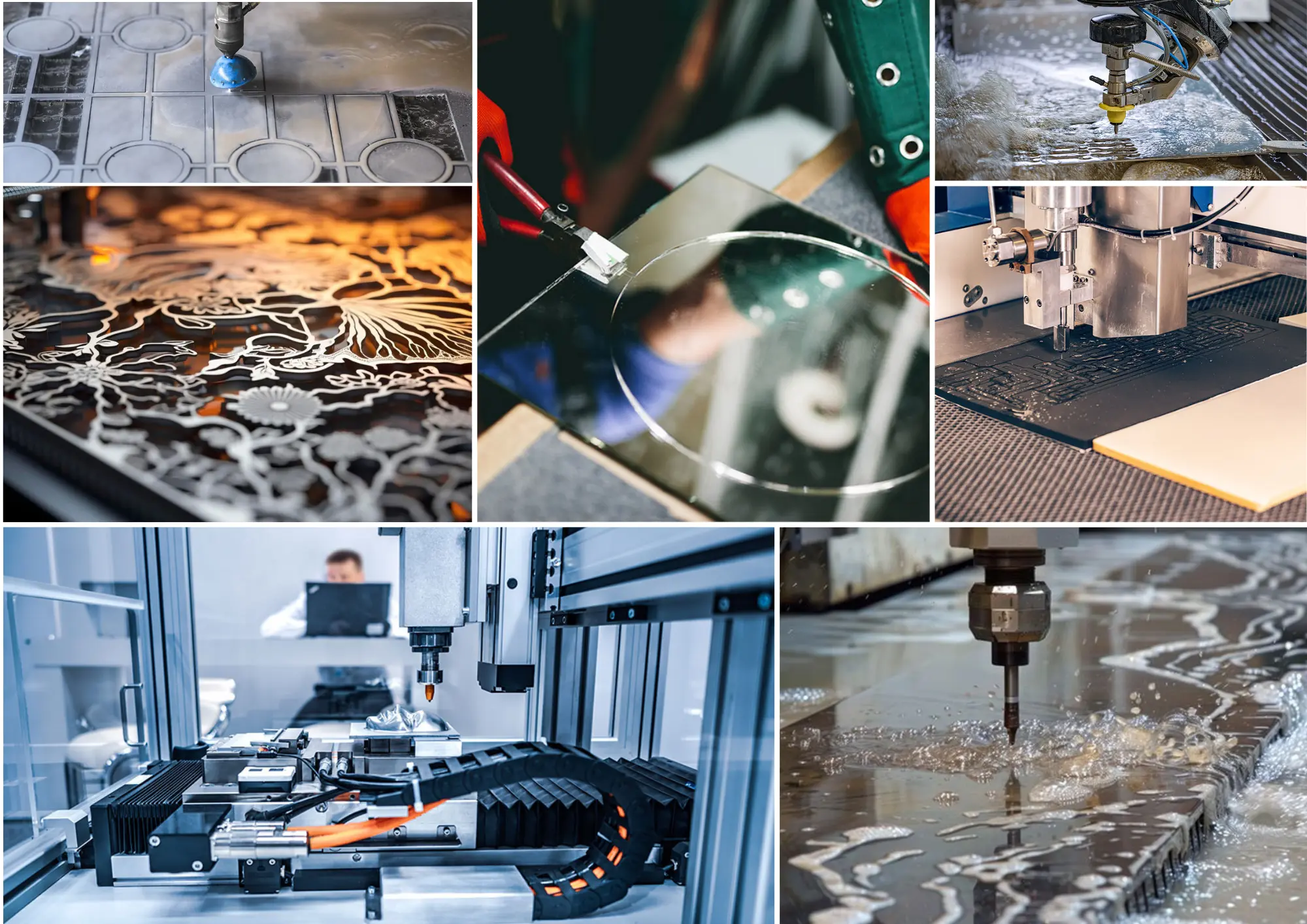

If you are looking for a solution that addresses all of the problems associated with conventional cutting methods such as plasma, laser, and EDM cutting, we recommend Hydro-Lazer’s waterjet cutting services. No project is too big or too small for us to handle. We can use our advanced water jet cutting machines on virtually any material without undesirable consequences such as heat-affected zones (HAZs), fumes or mechanical stress on the material being cut.

A Look at Hydro-Lazer’s Waterjet Cutting Solutions for Various Industries

At Hydro-Lazer, we strive to meet component and part creation requirements of customers through our hydro-jet cutting services. We understand that clients have high expectations when it comes to product manufacturing. Our waterjet cutting services are ideal as they can be used to cut a variety of materials at high speeds, with immense precision, and at competitive costs.

Some highlights of our capabilities

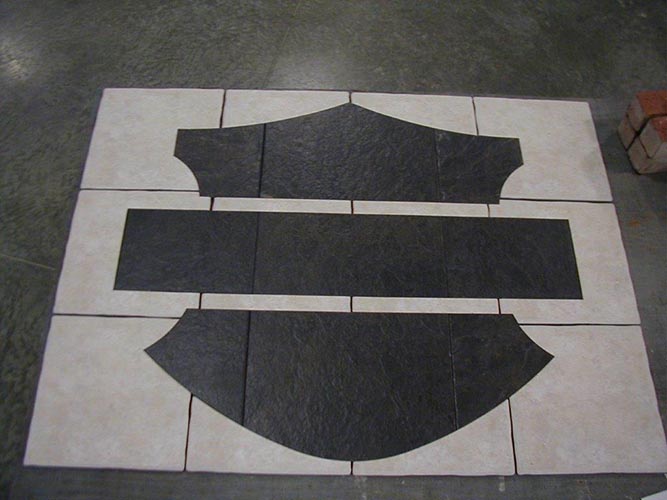

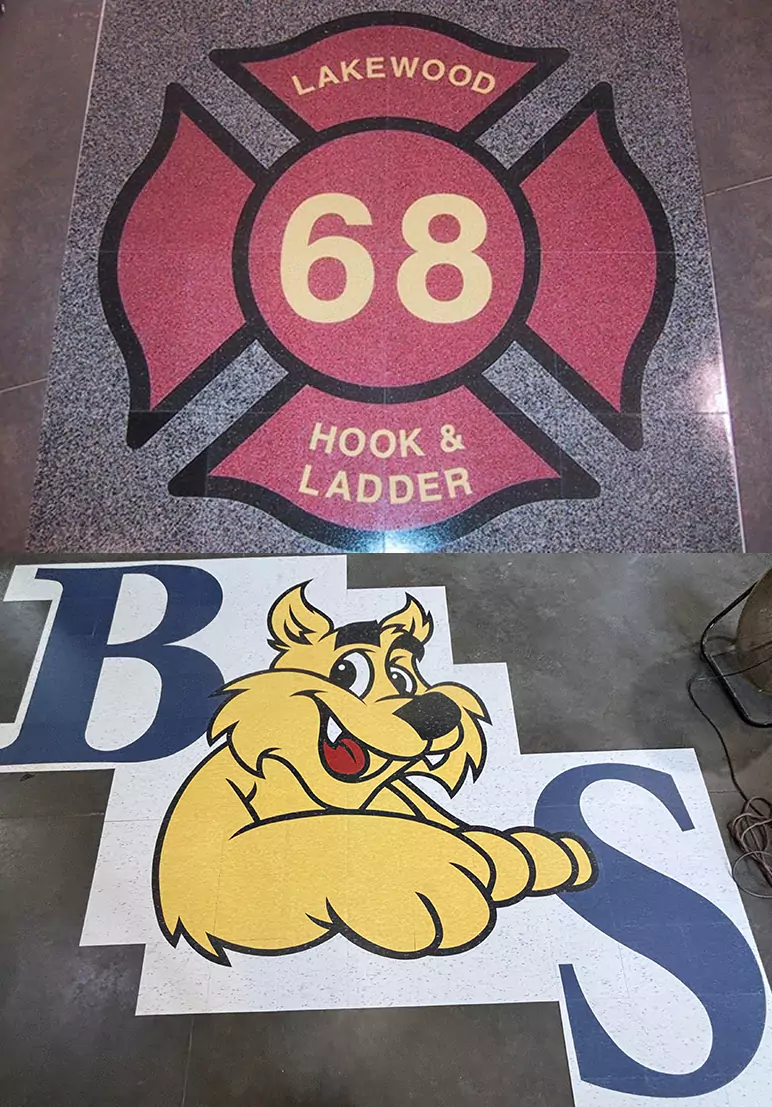

Production capability for any quantity including sizes up to 9 ft X 12 ft. We specialize in flooring inlays.

Our advanced systems utilize a high pressure (50,000 PSI) stream of water generated by a WSI 50 HP to cut virtually any material up to 8″ thick.

We can use your inputs in the form of hand sketches or CAD drawings, and render designs using offline programming and CAD digitizing software.

We employ leading-edge CNC and optical equipment to accurately cut complex shapes and contours within a .003″ tolerance on certain materials.

Our Latest Projects